In many industries, especially pharmaceuticals, food and beverage, microelectronics, and chemical processing, effective particle removal is a critical component of maintaining product quality and process reliability. One essential part of any fluid filtration system is the prefiltration stage — the first line of defense in removing contaminants and protecting downstream filters and equipment. Whether you’re looking to eliminate coarse particles, extend the lifespan of final filters, or maintain steady flow rates, selecting the right prefiltration setup can have a profound impact on both performance and cost-efficiency.

This article explores the two most common types of prefiltration — single-step and multiple-step — and how to choose the ideal system based on your specific process needs.

What Is Prefiltration?

Prefiltration is the process of removing larger particles and contaminants from a liquid or gas before it passes through finer, more sensitive filtration stages. By capturing debris early on, prefilters reduce the burden on final filters, help maintain high throughput, and increase the efficiency and reliability of the overall filtration system.

Prefiltration can be applied to a wide variety of systems, including water treatment, sterile manufacturing, beverage bottling, and industrial chemical production. The prefilter’s effectiveness depends on its media type, pore size, flow compatibility, and installation configuration.

Single-Step Prefiltration: Simple and Cost-Effective

Single-step prefiltration is the most straightforward form of particle removal. It typically involves one filter element installed upstream of the final filter. This configuration is most appropriate when the process fluid contains a relatively low particle load or a narrow range of particle sizes.

When to Use Single-Step Prefiltration:

- When large particles dominate the contamination profile

- For clear process streams with minimal particulate fluctuation

- In systems with low to moderate flow rates

- When cost or space constraints limit more complex setups

Common Media Types:

- Melt-Blown Polypropylene: Ideal for removing coarse particles in general industrial and water treatment applications.

- Nylon Cartridges: Useful for moderate chemical resistance and higher strength requirements.

- Pleated Depth Filters: Made of polypropylene or fiberglass, these filters offer greater surface area and retention capacity, suitable for higher flow rates or finer particulate removal.

Benefits of Single-Step Prefiltration:

Lower upfront cost and easy maintenance

- Reduced installation complexity

- Suitable for many general-purpose applications

- While single-step filtration is effective for many systems, it may not provide sufficient protection in processes with high solids content, variable particle sizes, or stringent final filtration requirements.

Multiple-Step Prefiltration: Enhanced Protection and Performance

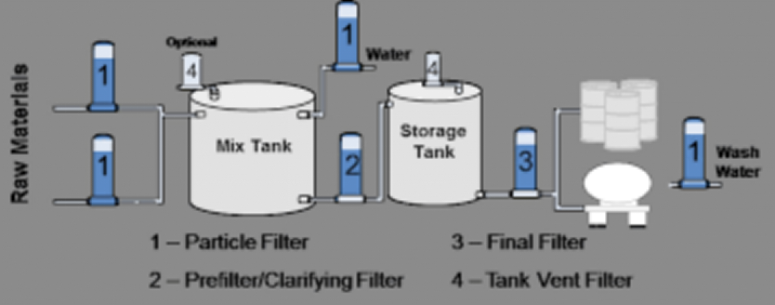

For more complex or high-load processes, a multiple-step prefiltration system is often required. This involves installing two or more filters in a series, with each one designed to remove progressively smaller particles. This tiered approach allows for better management of contaminant loads and improves the service life of each filter stage

Why Choose Multiple-Step Prefiltration?

High particle load in the fluid stream

- Broad range of particle sizes

- Sensitive downstream equipment or final filters that must be protected

- Critical operations that require uninterrupted filtration and minimized downtime

Example Configuration:

1.First Stage (Coarse Filter): Melt-blown polypropylene filter to remove large debris and prevent clogging of finer filters.

2.Second Stage (Intermediate Filter): Pleated depth filter to capture medium-sized particles and reduce the burden on the final filter.

3.Third Stage (Fine Filter): High-efficiency pleated media made from polypropylene or fiberglass to catch remaining fine particulates.

This configuration provides optimal balance between flow performance, filter life, and process protection.

Advantages of Multiple-Step Systems:

Prolongs the lifespan of downstream filters

Increases total throughput

Reduces filter change-out frequency

Enhances overall process consistency

Lowers total cost of ownership through better filter utilization

It’s important to note that the number of stages and the specific filters used must be tailored to the characteristics of the fluid — including viscosity, particle distribution, temperature, and chemical compatibility.

Integrated Prefiltration: Multi-Layer Filters in a Single Module

An increasingly popular solution in modern filtration systems is the use of integrated prefiltration — where multiple layers of filter media are built into a single pleated cartridge. This approach delivers the benefits of multiple-step filtration with the convenience and compactness of a single unit.

Key Benefits:

Space-saving design

- Simplified maintenance and installation

- Effective particle separation in a single housing

- Reduced pressure drop compared to separate filters

These cartridges are especially useful in systems with limited space or those requiring frequent filter changes.

Factors to Consider When Designing a Prefiltration System

To achieve optimal results, several factors should be considered when selecting a prefiltration system:

Pore Size and Distribution: Determines the size of particles the filter will retain. Gradual reduction of pore sizes across stages ensures more effective filtration.

Media Type: Different materials (e.g., polypropylene, fiberglass, nylon) offer different levels of chemical resistance, flow capacity, and durability.

Fluid Compatibility: Ensure all filter components are compatible with the process fluid to prevent degradation or contamination.

Flow Rate and Pressure Requirements: Each filter must be sized to handle the system’s flow rate without excessive pressure drop.

Filter Life and Change-Out Frequency: Balance the filtration performance with the expected operational lifespan to optimize maintenance intervals.

Working with a Filtration Expert

Designing a successful prefiltration setup isn’t just about choosing filters off the shelf — it requires a detailed understanding of the entire process. Partnering with a filtration expert or working with a dedicated applications lab can help:

- Conduct lab-based or field testing

- Determine ideal pore sizes and configurations

- Evaluate filter performance over time

- Ensure regulatory and safety compliance

The Critical Process Filtration Applications Lab, for example, provides hands-on support for evaluating prefiltration systems and fine-tuning setups to specific process needs.

Build Your Filtration Strategy on a Solid Foundation

Whether you’re starting from scratch or optimizing an existing system, effective prefiltration is essential to achieving clarity, consistency, and cost control in your process. From simple single-step filters to advanced multi-stage configurations or integrated cartridges, SANAKY and its industry partners offer a broad range of solutions tailored to your specific challenges.

By investing in the right prefiltration strategy today, you’re protecting your process tomorrow — improving quality, reducing downtime, and ultimately supporting long-term operational success.

-------------------------------------------------------------------------------------------------------------

SANAKY VIETNAM., CO LTD - Manufacturer of Chest Freezer - Upright Cooler, Transformer, RO Water Purifier...

Vietnamese

Vietnamese  English

English  Chinese

Chinese  French

French  Spanish

Spanish  Russian

Russian  Arabic

Arabic  Portuguese

Portuguese